Innkeeper delivers pressure testing products designed for the needs of supplier R&D and equipment manufacturers. We supply multi-variable component testing systems that control the applied fluid pressure, flow and temperature.

Pressure

Advanced Pressure Testing

Combining pressure, flow and thermal control

Advanced Pressure Testing

Under PRESSURE?

Advantages

Whatever combination of pressure, flow and thermal parameters you need, the PRESSURE control interfaces with actuators, sensors, command, and safety signals to simulate real-world stresses on your components and assemblies.

Replace + Expansion

If you plan to upgrade existing equipment, consider how new closed loop controls could breathe new life into your system. New InnControl™ software will enhance test automation and safety, and new fluid components will improve control response and accuracy. Innkeeper has experience in a broad range of equipment retrofits which reduce the extent of new capital purchasing.

Value

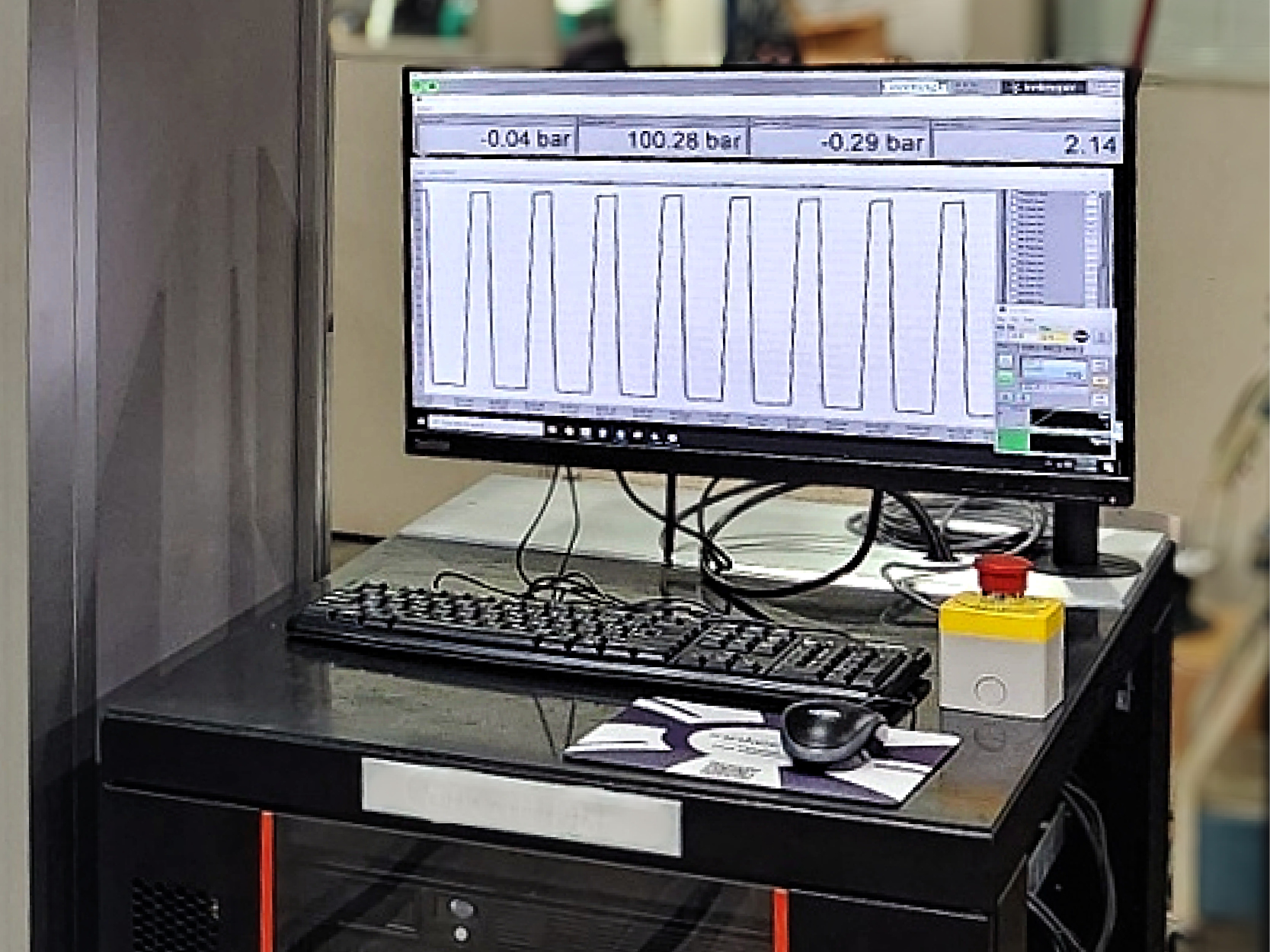

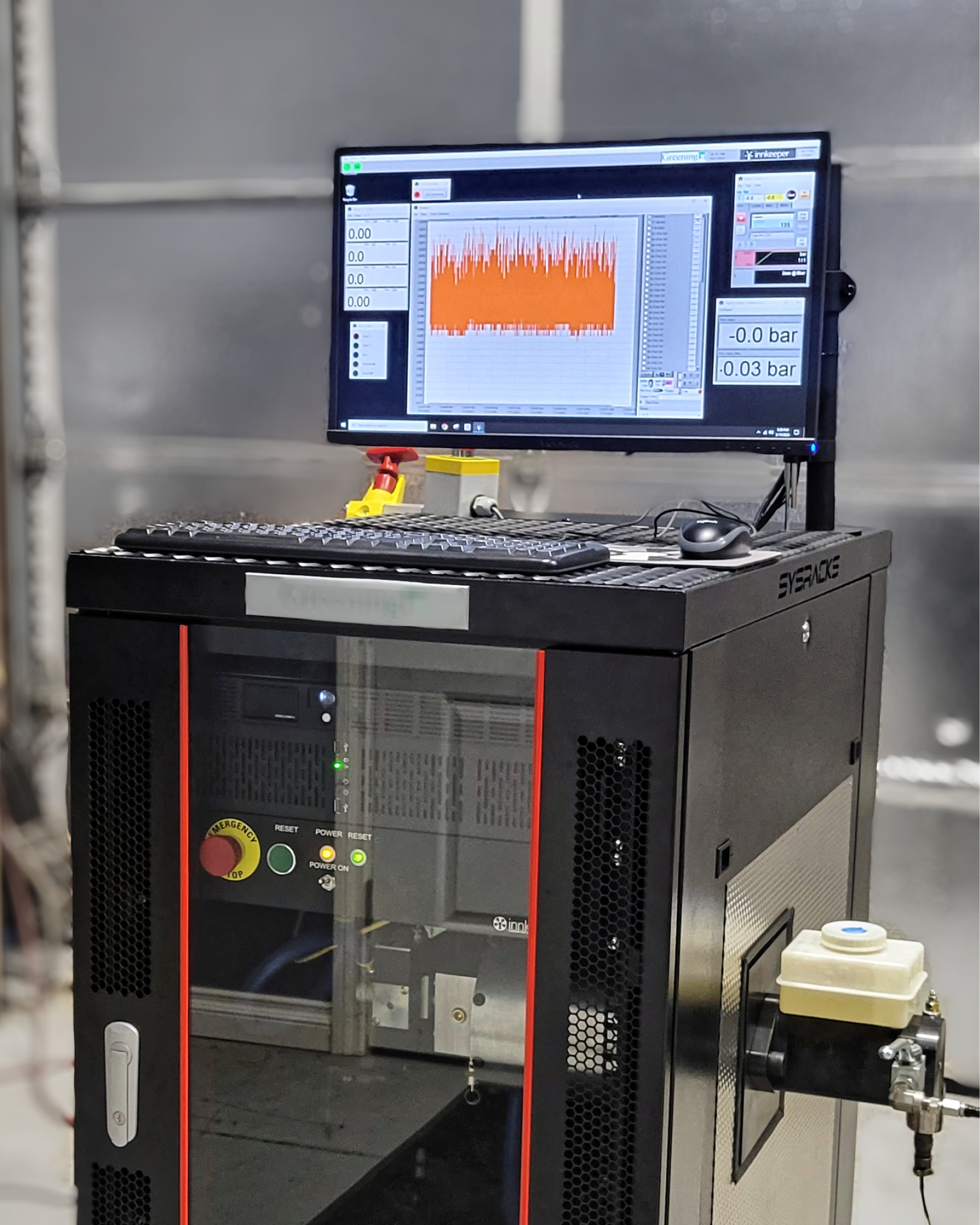

PRESSURE solutions are designed to balance cost, function, flexibility, and stability inherent in all closed-loop controllers. Through thoughtful integration of widely available components and a User Interface centered around the needs of both the test engineer and the operator, InnControl delivers a dependable, low-risk, and cost-effective control system. Developed for flexible integration, InnControl™ adapts to various hardware types, is easy to configure, and boasts a user-friendly interface. It excels in controlling hydraulic, pneumatic, and electro-mechanical systems for pressure control. Its intuitive design reduces setup errors, offering a flexible testing tool built with the end-user in mind.

Field Support

When it comes to field support, we excel both in-person and remote access. Our prompt response and comprehensive assistance set us apart. However, InnControl systems don’t rely solely on Innkeeper support. We provide all sub-component documentation and a full system diagram with every project, empowering any qualified technician to isolate and replace any individual component if needed. Choose InnControl and Innkeeper for your testing needs – because we’re not just about testing, we’re about building your solutions.

Advanced Pressure Testing

Purpose Built

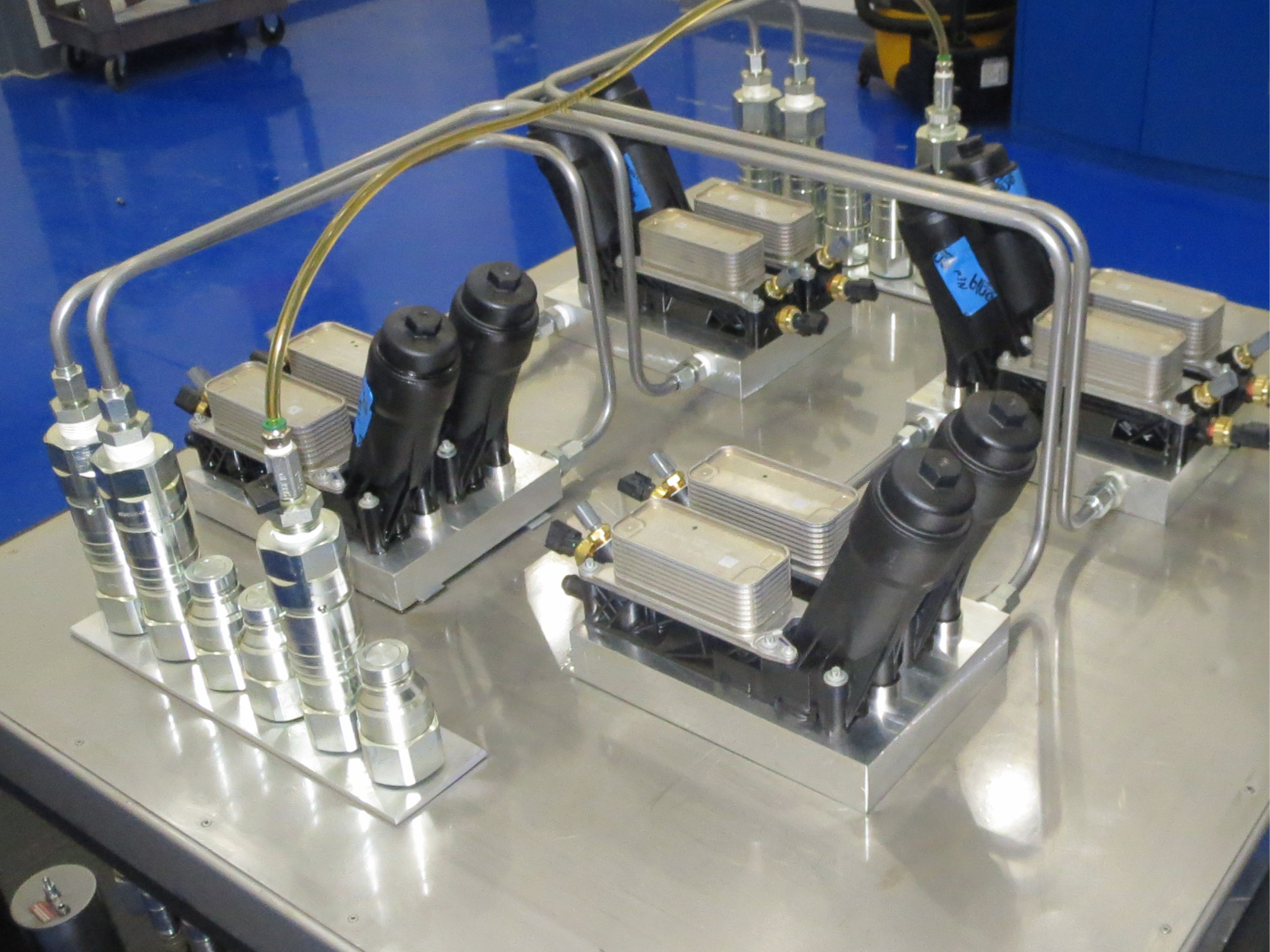

Precise control of fluid Pressure and Flow is a critical requirement in product durability testing. Innkeeper LLC is an experienced supplier of test rigs in the automotive, aviation and marine industries that require closed-loop and discrete controls where the fluid (sometimes air) acts directly on the component under test. These systems are related to the AXIS product, but the unique applications deserve special attention. There are many options available to mix and match a winning solution.

What is common to all of the different types of pressure test equipment is the design selection process. There are many factors that need to be considered when designing a pressure testing machine, starting with whether it is a static, quasi-static or dynamic pressure requirement and then details of the test specimen characteristics and actual test specifications, simultaneous specimens, simultaneous flow and temperature control. The underlying controls are similar to our AXIS systems, but system design is unique.

Advanced Pressure Testing

Actuation Options

- Full Closed Loop – Closed loop technology is paired with InnControl software to command the device with minimum error. Hydraulic and electric screw actuators are the primary choices and this achieves the highest frequency response, best precision and flexibility.

- Proportional Pressure for precise peak force output – the use of pneumatics reduces the costs, but only peak force and position are controlled.

- Discrete Closed Loop, to peak values – the use of pneumatics makes this the least costly option, but sensitive to air supply pressure with moderate peak position control.

- Discrete Closed Loop for threshold values – electric actuators used in discrete control mode save on control electronics and have better response than pneumatics. When threshold control is all that is required this is an excellent option.

Advanced Pressure Testing

Development

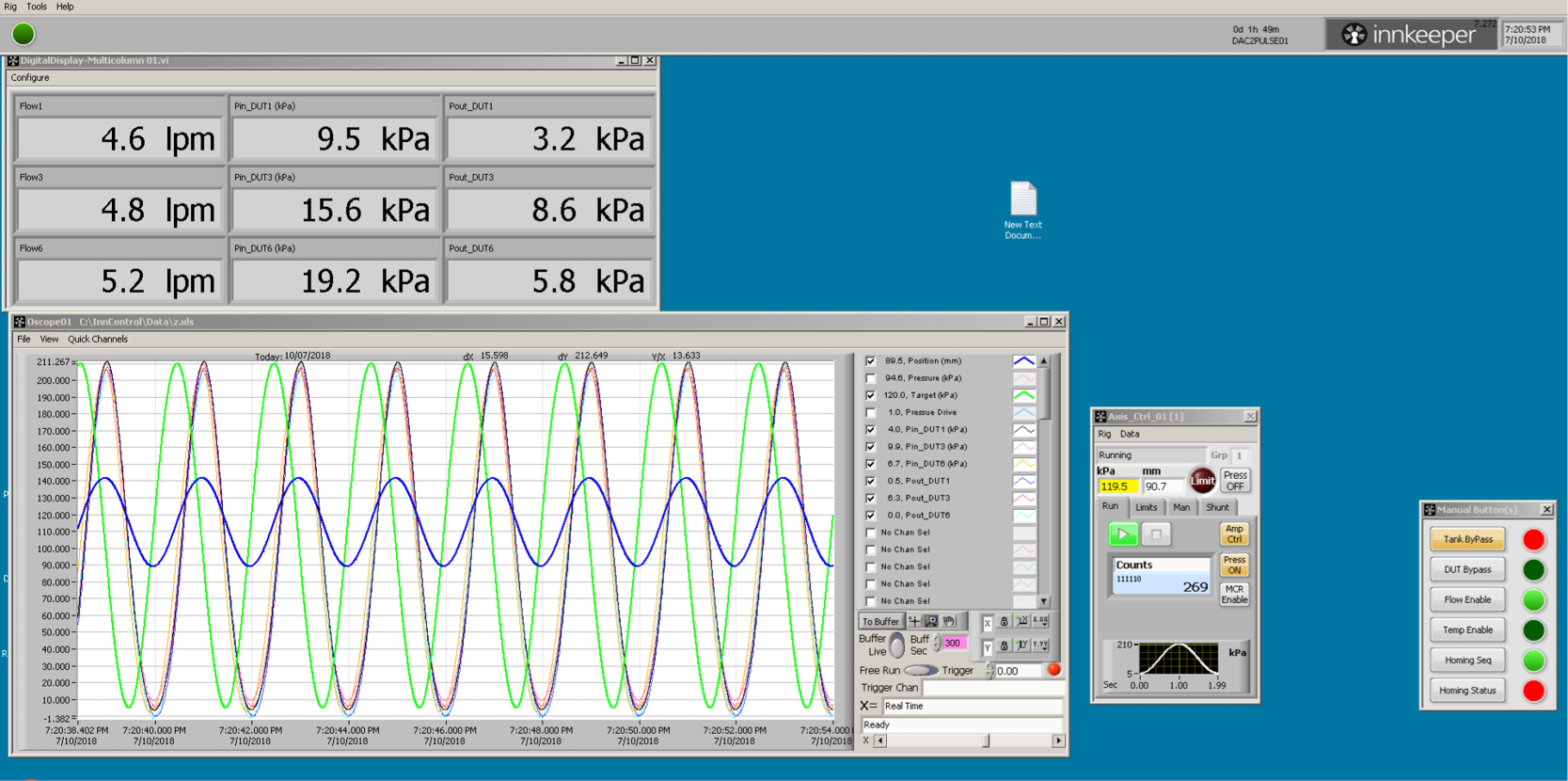

Operating and maintaining product testing labs are a challenge because of the variety of configuration requirements. Innkeeper developed controls for pressure testing so that operators can easily configure tests and obtain reliable information. The InnControl test system provides flexibility so that new permutations can be applied by the test engineers with minimal external support. The GUI allows for the application of complex waveforms to each control channel.

Advanced Pressure Testing

Control Features

Both types of control systems are packed with features, including these:

- Single or multiple control mode operation.

- Compact control drawer height, perfect for typical 19” equipment racks or tabletop use.

- Customer-modifiable actuator configurations.

- High-resolution control electronics.

- Fast update rates for control loop and feedback signals.

- Flexibility to work individually or as a phase-locked multi-axis test.

- Compatibility with Hydraulic, Electro-Mechanical and Pneumatic actuators.

- Conditioning for LVDT, Load Cells, and String Pots.

- Standard single-phase 115VAC power outlet compatibility.

- Emergency Stop pushbutton on the controller front panel and dedicated connector for additional ESTOP daisy chain links.

- English language control text and manuals.

Markets and Applications

Innkeeper controls offer a versatile solution for the testing of components and subassemblies. Within the vehicle market our primary customers have represented the areas of;

- Automotive

- Motorsports

- Aviation

- Defense

- Electric vehicles and support systems

The test applications are unique to each type of component. Pressure and flow testing then branch into tests that include combinations of;

- Durability (overall description)

- Burst

- Cyclic fatigue

- Pressurization

- Characterization

- Heating and Cooling

- Charging

- Brake cycle and characterization

What are you Testing

- Air conditioning line (AC tubing/piping)

- Air preheaters

- Battery thermal management

- Bleed air cooler

- Chiller

- Condensers

- Economizers,

- Evaporators

- EV charger heat exchangers

- Filters (fuel, oil, other viscous stuff)

- Heat exchangers (shell-and-tube, plate-and-frame, or finned-tube heat exchangers, cold plate, cartridge, air to liquid, liquid to liquid)

- Heat pump

- Heat sink / vapor chamber

- Heater cores

- Hydraulic oil heat exchanger

- Intercoolers

- Motor winding cooling

- Radiators

- Vehicle Brake cylinders

- Water charge Air coolers

Example: Brake Characterization

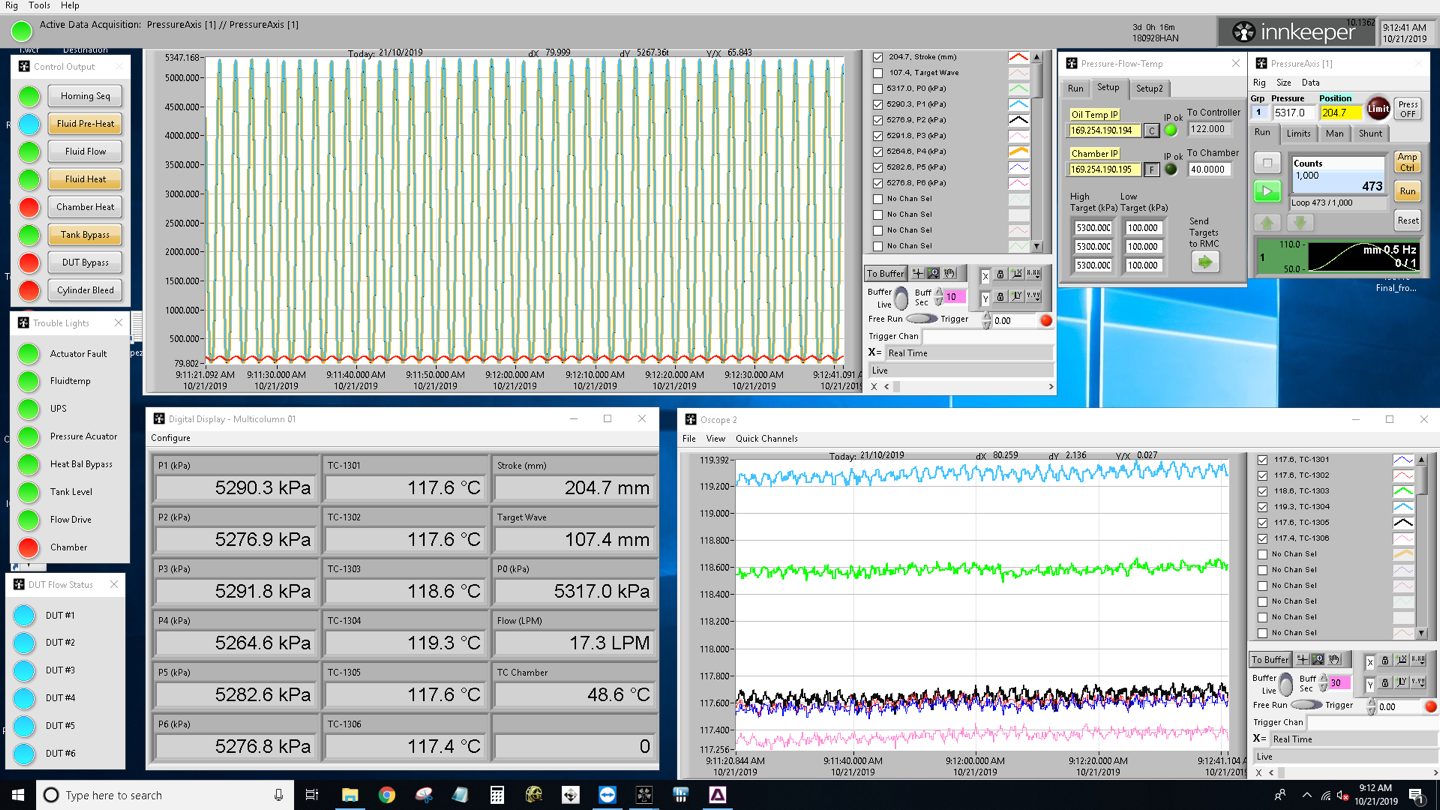

Example: Pressure Temperature Flow Durability

Example: Radiator Pressure Cycle

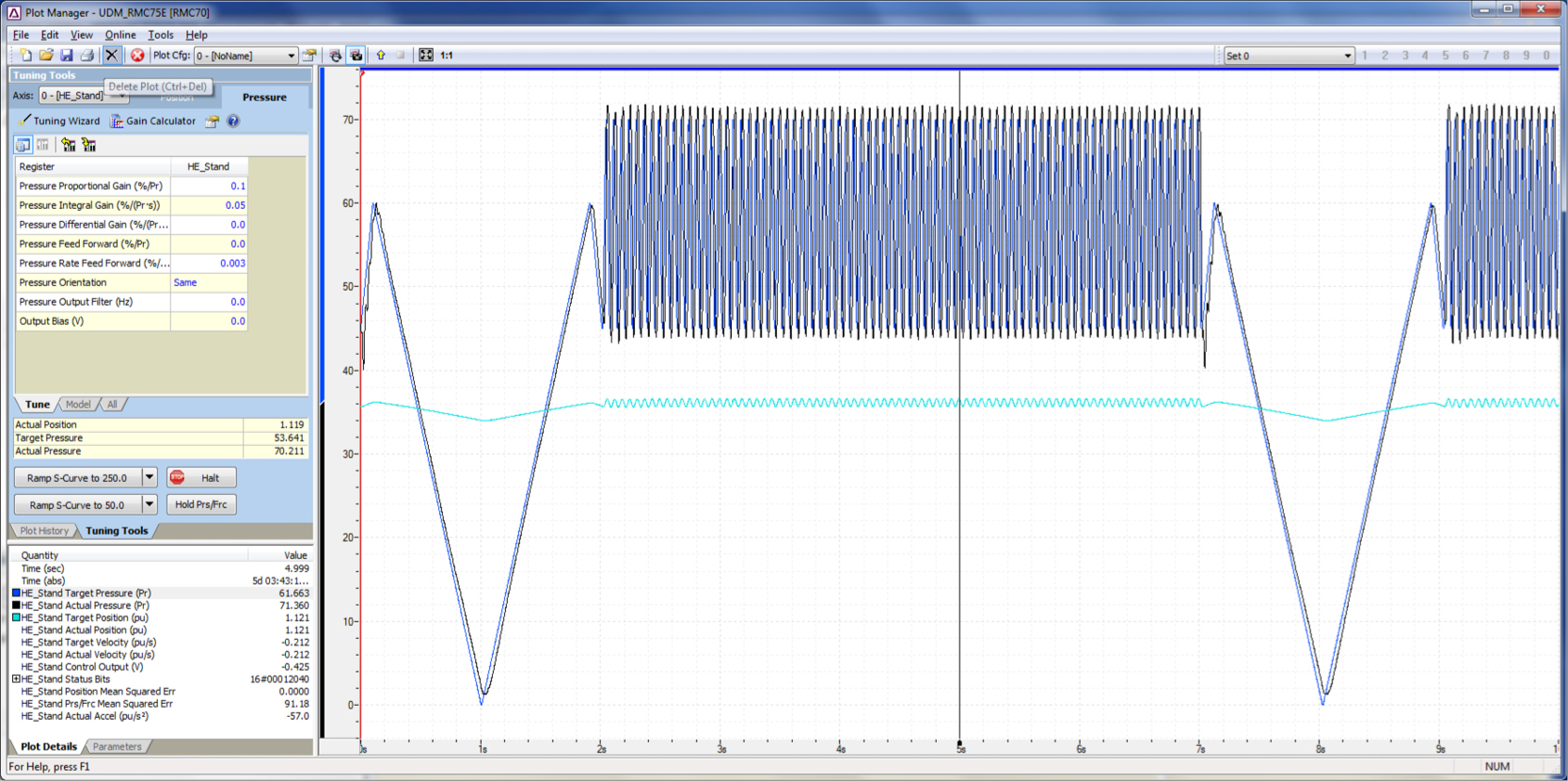

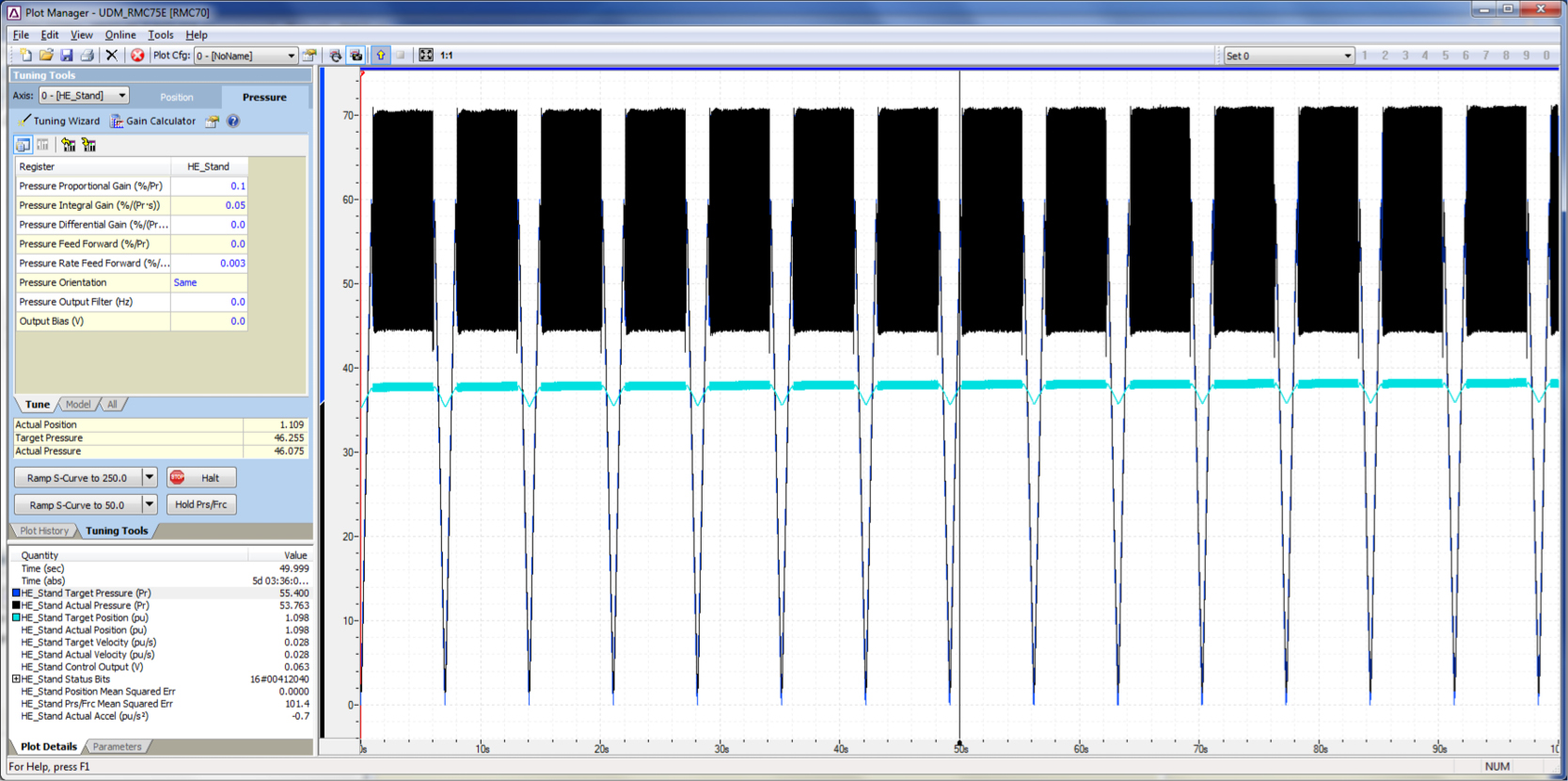

Example: Complex Pressure Waveform

“These two screen are courtesy of Delta Motion, RMCTools, Plot Manager, using Innkeeper data”.

Take Control of Your Testing

In a world that’s constantly evolving, it’s crucial to have equipment that can adapt and grow with you. Our PRESSURE control product is designed to do just that—offering precision, flexibility, and ease of use for all your testing needs.

Don’t let outdated equipment hold you back. Embrace the future of testing with retrofits by Innkeeper LLC. It’s not just an investment in a tool—it’s an investment in the continued success of your lab or testing team.

Ready to take the next step? Contact us today to discuss how InnControl and our engineering services can revolutionize your testing process. Our team of experts is ready to help tailor a solution to fit your unique needs.

Contact Us

How Can We Help You?

We welcome your questions, comments, and suggestions. Whether you’re seeking information about our products, services, or just want to connect, our team is ready to assist.

Contact Details:

Phone: (734) 743-1707

Email: info@innkeeperllc.com

Address: 4902 Dewitt Rd. Suite 104, Canton, Michigan 48188

Hours of Operation:

Mon – Fri 8:00 am – 4:30 pm

Sat – Sun Closed

Download Brochure

Download our Brochure

Discover all that Innkeeper LLC has to offer. Fill out the form below and select a brochure to explore our services and learn how we can enhance your experience!

Subscribe

Stay Connected

Not everybody wants to receive more information, but we would be happy to send you updates and make you aware of new products and applications. Leave your contact details below.